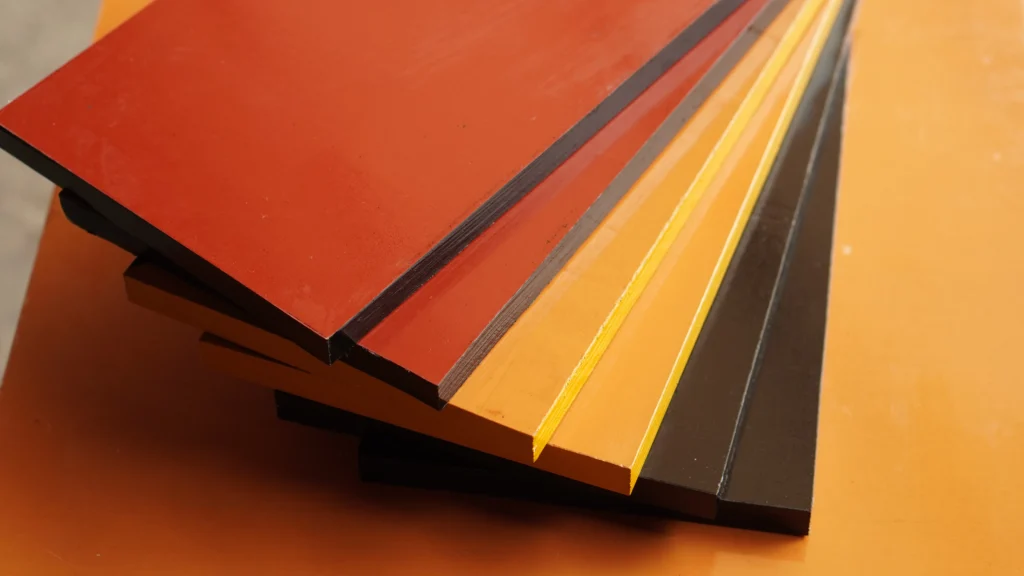

Available Finishes

Sizes & Thickness

Highlights construction, testing parameters, and on-site performance for formwork applications.

Designed to withstand the hydrostatic pressure of freshly poured concrete, ensuring stable formwork and precise casting without deformation.

2]Strong Bonding & Dimensional Stability

Bonded with PF/MR resin for excellent internal strength. This reduces warping, delamination, and dimensional changes caused by moisture or temperature variations.

Film-faced and calibrated panels provide an even, uniform surface finish, reducing the need for additional plastering or surface correction after de-shuttering.

Resin-sealed edges and a moisture-resistant surface extend product life, allowing repeated use without compromising performance.

Resistant to moisture, abrasion, chemicals, and rough site handling, making it suitable for long-term construction use in challenging environments.

Our shuttering plywood is widely used across construction and infrastructure projects:

Slab and beam formwork

Column and wall shuttering

Bridges, flyovers, and infrastructure casting

Residential and commercial construction

Precast concrete production

Every sheet is tested to meet construction-grade requirements and ensure consistent quality:

72-hour BWP water resistance testing

Bending strength and load performance checks

Glue shear strength validation

Nail and screw holding capacity tests

Swelling and dimensional stability assessment

Reusability cycle evaluation

These tests help ensure dependable performance across repeated casting cycles and varied site conditions.

Our shuttering plywood is designed with practical site requirements in mind — strength where it matters, finish where it counts, and durability that supports repeated use. It’s a dependable choice for contractors, builders, and infrastructure developers who value performance over promises.

Film-faced surfaces deliver smooth, uniform concrete finishes with minimal surface correction.

Cleaning after use, edge sealing, and correct storage significantly improve reuse life.

Yes. It is suitable for slabs, beams, columns, and wall shuttering when properly supported.

It is designed and tested for high water resistance and site durability.

Store flat, off the ground, and away from standing water to preserve strength and surface quality.