Available Finishes

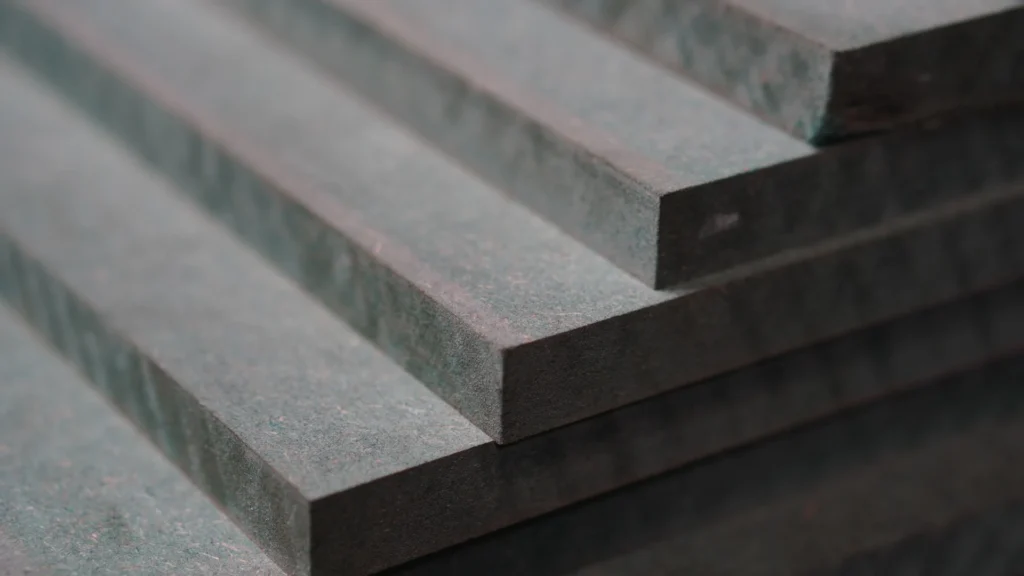

Sizes & Thickness

Covers density, durability, and stability built for demanding interior and structural needs.

The compact fiber composition provides enhanced strength, load-bearing capability, and resistance to surface impact.

2]Improved Screw-Holding Performance

Higher density allows better holding strength for fasteners and fittings, supporting demanding furniture and interior applications.

The refined surface supports laminating, veneering, and decorative finishes with consistent bonding and appearance.

Controlled manufacturing reduces the risk of deformation, maintaining flatness under normal interior conditions.

Automated production and in-house quality checks ensure uniform thickness, density, and performance across large production batches.

Drumini HDF is commonly used in applications that require higher strength and durability, including:

Furniture components requiring added strength

Door skins and interior shutters

Wall panels and high-use interior surfaces

Flooring substrates and underlayment

CNC-machined components and precision panels

Each batch of Drumini HDF is tested to ensure dependable performance and safe interior use:

Density and structural consistency testing

Bending strength and load resistance checks

Internal bond strength verification

Screw-holding capacity testing

Thickness swelling assessment

Surface adhesion testing

These tests help ensure long-term durability and consistent performance across applications.

Drumini HDF is designed for manufacturers, designers, and builders who need materials that perform under pressure. With its higher density, strength, and stability, it supports applications where standard boards may fall short.

A dependable solution for interiors and components built to last.

HDF is preferred when higher strength, impact resistance, or load-bearing capacity is required.

Yes. Its dense structure makes it suitable for flooring substrates, door skins, and heavy-use panels.

Yes. HDF generally provides improved screw-holding due to higher density.

Yes. HDF provides a smooth, stable surface for lamination and decorative finishes.

Drumini HDF is engineered to maintain dimensional stability under normal interior conditions.