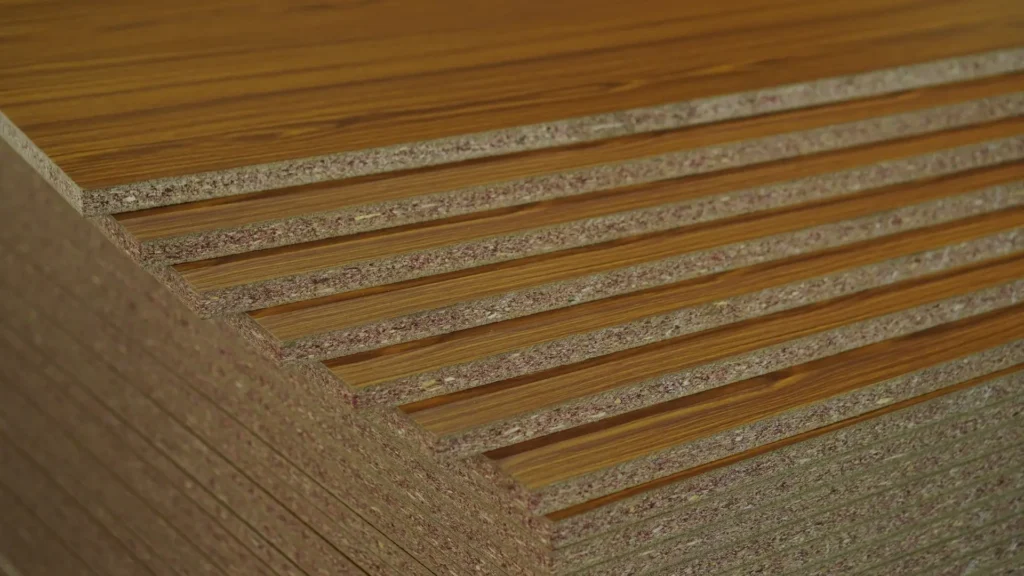

Sizes & Thickness

Explains the material composition, performance consistency, and responsible manufacturing approach.

1]Eco-Friendly Raw Material

Manufactured using sugarcane bagasse, an agricultural by-product, these boards significantly reduce reliance on virgin timber and support circular manufacturing practices.

2]Strong & Stable Panel Structure

Engineered for uniform density and internal bonding, Bagasse Boards offer dependable strength and dimensional stability across varying environmental conditions.

Controlled manufacturing processes help reduce swelling and warping, making the boards suitable for interior environments with changing humidity levels.

Fine surface quality ensures excellent compatibility with laminates, veneers, and finishes, supporting clean aesthetics and precision furniture work.

Automated production and in-house quality control ensure uniform thickness, strength, and performance across every batch, making the boards ideal for OEM and modular furniture manufacturing.

Drumini Bagasse Boards are widely used in residential and commercial interior applications, including:

Modular and ready-to-assemble furniture

Cabinets, wardrobes, and storage units

Interior paneling and partitions

Shelving and non-structural furniture components

Office and institutional furniture

Each Bagasse Board is tested to ensure long-lasting performance and safe indoor use:

Density and moisture stability testing

Internal bond strength verification

Bending strength and load resistance checks

Screw and nail holding capacity testing

Thickness swelling assessment

Surface adhesion testing

E1 / E0 emission standard compliance

These tests ensure the boards meet quality expectations for furniture manufacturing while maintaining low-emission, indoor-safe standards.

Drumini Bagasse Boards are designed for manufacturers, designers, and builders who want materials that balance performance with responsibility. They offer the strength needed for daily use, the consistency required for mass production, and the sustainability of today’s market increasingly values.

A reliable choice for interiors that are built to last and built with purpose.

Bagasse boards offer comparable strength with added sustainability benefits due to agri-waste usage.

Yes. It supports consistent machining and finishing required for modular and flat-pack furniture.

Yes. Its surface quality allows proper bonding of laminates and decorative finishes.

When used appropriately, bagasse boards maintain stability similar to conventional interior-grade boards.

Yes. Drumini bagasse boards are designed for durability and consistent performance in interior environments.